Choosing the right aggregate can make or break an outdoor project, whether you’re building a driveway, stabilizing a foundation base, or shaping a landscape for better water management. With its angular shape and consistent gradation, 57 Limestone is a practical, versatile option that balances performance with cost across a range of applications. The stone’s typical size—about three-quarters of an inch on average—creates reliable voids for drainage while still forming a firm base under repeated loads. If you’re comparing base materials for upcoming work, Check Now with local specifications so the stone you purchase aligns with project requirements. Throughout this guide, you’ll find clear, actionable insights into selection, installation, and maintenance, plus where 57 Limestone Gravel fits best in both functional and aesthetic designs.

How 57 Limestone Improves Drainage in Driveways and Foundations

Effective drainage starts with aggregate shape, size, and consistency, and 57 Limestone delivers on all three. Its angular particles interlock enough to resist movement, while the gradation maintains continuous void paths that let water pass through quickly. That combination limits hydrostatic pressure under slabs and pavements and helps reduce frost heave in cold climates. In driveways, it works as a free-draining base or sub-base that channels water away from the surface and into properly designed outlets. Around foundations, a well-wrapped bed of stone supports footings and pipe systems so moisture never lingers against critical structures.

Key drainage mechanics explained

The drainage benefit hinges on the stone’s stable void ratio—large enough to move water, tight enough to protect against settlement. A layer of 57 Limestone over compacted subgrade, separated by a geotextile to prevent fines migration, maintains permeability through storm cycles. For perimeter drains and daylighted trenches, the stone surrounds perforated pipe, and the system is wrapped in fabric to keep sediment out. When grading for driveways, maintain a slight crown or cross-slope so surface water seeks the shoulders instead of ponding. Combined with gutters, downspout extensions, and positive grading away from structures, this approach keeps the base dry and extends the life of asphalt, concrete, or pavers above.

Load-Bearing Properties That Support Structural Stability

Structural stability relies on distributing loads through the aggregate layer into the subgrade without excessive deflection or rutting. The angular geometry of 57 Limestone promotes interlock, which helps transfer wheel or point loads laterally rather than directly downward. Although it’s not a dense graded mix, the stone’s structure still delivers dependable support when placed in properly compacted lifts. For patios, sidewalks, and light-vehicle driveways, it forms a base that resists pumping and shifting under seasonal moisture changes. On weak subgrades, pairing the stone with geogrid or a geotextile separator often improves bearing capacity and long-term performance.

Designing base layers for different loads

Base thickness should be matched to expected loads and subgrade strength, with common practice ranging from a few inches for walkways to a foot or more for heavy-use drive lanes. Compact in 4–6 inch lifts with a vibratory plate or roller so the aggregate seats and interlocks across the layer. When a tight surface is needed for pavers or slabs, contractors often “choke” the top of 57 Limestone with finer screenings to limit point loading and improve bedding. Mind edge restraint: strong borders limit lateral spread and help the base carry repeated loads without losing shape. Keep moisture in check with proper drainage layers and slopes, as saturated subgrades undermine any aggregate’s load-bearing potential.

Effective Use in Erosion Control and Landscape Grading

Erosion is as much about energy as it is about water volume, and the mass and angular edges of 57 Limestone help dissipate that energy. Along swales, culvert outlets, and the toe of slopes, it slows flow velocities and stabilizes soils vulnerable to washouts. The stone’s size allows infiltration while resisting displacement, which reduces sediment transport and preserves intended grades. Because it’s limestone, the material also brings a modest buffering effect that’s generally compatible with garden soils and turf areas. Used thoughtfully, it creates a rugged, low-maintenance barrier where fine soil alone would quickly erode.

Practical grading strategies

Start by shaping the subgrade to move water where it should go—away from structures and toward vegetation or engineered drainage. Add a fabric separator before placing stone on fine or loamy soils to prevent mixing that clogs voids and weakens the layer. In areas with concentrated flow, place 57 Limestone thicker and key it into the slope to limit undercutting; adding small terraces helps spread energy. Maintain a consistent cross-slope on paths and driveway shoulders so stormwater never stalls and saturates the base. Regular visual checks after heavy rain help you spot rilling or displacement early, when a quick regrade and top-up of stone can prevent larger repairs.

Sourcing and Material Quality Considerations for 2025 Projects

Material consistency is the backbone of predictable performance, so sourcing matters as much as installation. In 2025, many suppliers publish gradation data and environmental disclosures, making it easier to compare options beyond price alone. Look for 57 Limestone that meets recognized sizing standards and shows minimal fines content for drainage uses, or confirm whether a blend is intended when densifying the surface. Ask about absorption and durability ratings, as lower absorption tends to resist freeze-thaw cycling. If color uniformity is important for visible applications, request a sample or yard visit before committing to a large order of 57 Limestone Gravel.

Verifying consistency and compliance

A reliable supplier should provide recent sieve analyses that demonstrate the stone falls within the expected gradation band for #57-size aggregate. Verify that deleterious materials—clays, organics, or soft rock—are within acceptable limits to avoid breakdown in service. Increasingly, public and private projects request Environmental Product Declarations; if sustainability is on your checklist, Check Now whether your quarry offers EPDs or recycled-content options that still meet performance needs. Confirm moisture conditions at delivery—material arriving saturated may compact differently and weigh more, affecting cost and placement rates. Finally, align your order with local specs and application: drainage fields favor cleaner stone, while base layers under pavers may call for a top choke of finer aggregate.

Installation and Compaction Tips for Long-Term Performance

Good outcomes start with subgrade preparation, because even the best stone cannot overcome weak or saturated soils. Excavate to the design depth, proof-roll to identify soft spots, and shore up problem areas with geotextile or a thin stabilization layer before placing aggregate. Install a separator fabric where fines could migrate upward into the 57 Limestone, preserving drainage and structure. Place the stone in uniform lifts, keeping each layer thin enough to compact thoroughly with available equipment. Maintain your planned slopes throughout placement so the base carries water away rather than trapping it.

Moisture, edge control, and settlement

While 57 Limestone isn’t a dense-graded mix, it still benefits from vibratory compaction that seats particles and improves interlock. If you need a tighter surface—for instance under pavers—add a light “choke” course of screenings or stone dust and compact again to lock everything together. Edge restraints—curbing, staked bender board, or concrete ribbon—prevent lateral spread and maintain the base geometry under loads. After the first heavy rain, inspect for settlement at transitions and re-level promptly before surfacing materials exaggerate low spots. Keep heavy equipment off freshly placed layers until compaction is complete, and re-compact after utility trench work intersects your base.

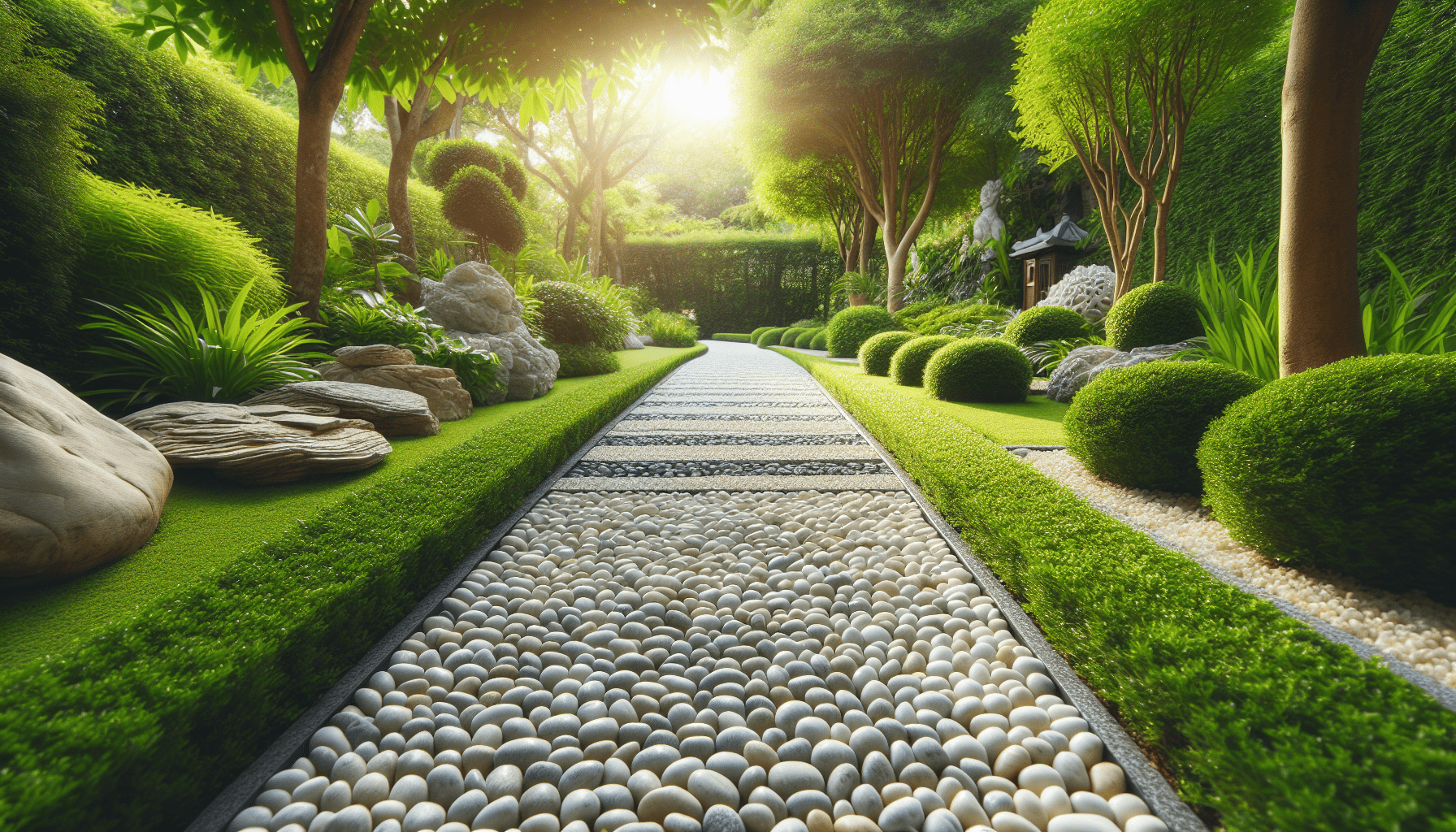

Aesthetic Uses for Decorative Ground Cover and Pathways

Function aside, 57 Limestone also works beautifully as a landscape accent. The light, neutral color brightens shaded areas and contrasts cleanly with dark mulch, evergreen foliage, or steel edging. As a ground cover, it suppresses weeds when paired with a breathable fabric and reduces splashing dirt onto siding or fence panels. For footpaths, the roughly three-quarter-inch size feels firm underfoot, especially when lightly choked to reduce scatter. Around trees and beds, it offers a crisp, long-lasting finish that doesn’t fade like organic mulch and is easy to refresh.

Design cues that blend form and function

Aim for a consistent path width and a smooth, compacted profile so wheelbarrows and strollers roll without fuss. Integrate stepping stones or pavers where you want visual rhythm and extra traction, allowing the 57 Limestone to fill joint gaps for a unified look. Tie in sleek edging—steel, aluminum, or dense composite—to create clean lines and contain the stone over time. Consider lighting: pale limestone reflects low-voltage path lights, enhancing nighttime visibility and curb appeal. If you’re pairing materials, use 57 Limestone Gravel in defined zones rather than mixing with rounded river rock in one area, maintaining both design intent and functional drainage.

Why 57 Limestone Remains a Cost-Efficient Choice for Outdoor Work

Cost efficiency isn’t just the sticker price per ton; it’s what the material delivers over its service life. With solid drainage, stable interlock, and low maintenance requirements, 57 Limestone often reduces callbacks, rut repair, and water-related failures. Availability in many regions keeps transport costs manageable, and consistent gradation speeds installation. Its durability through freeze-thaw and wet seasons means you won’t replace or rework bases as often compared to weaker aggregates. For homeowners and contractors alike, those savings add up across driveways, pathways, and foundation projects.

Budget planning and value engineering

Plan quantities carefully by confirming depth after compaction, then adding a small contingency to cover settlement and minor grade corrections. Coordinate delivery with site readiness so trucks can tip close to the work area, cutting rehandling time and labor. When comparing aggregates, weigh the hidden costs: pea gravel rolls under tires, rounded stone compacts poorly, and recycled mixes may include fines that compromise drainage unless screened. For visible zones, factor in the reduced refresh cycle—limestone’s color stability keeps projects looking sharp season after season. If you’re aligning orders with performance specs or sustainability goals, Check Now with suppliers on gradation, EPD availability, and recommended blends so you get the best value from 57 Limestone Gravel without surprises.